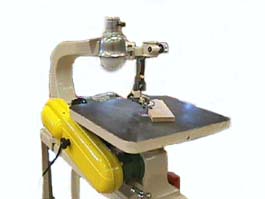

Scroll Saw

|

|

The scroll saw is designed to cut curves and internal cuts. This machine uses a reciprocating action. The scroll saw cuts on the down stroke of the blade. It is a stationary machine and should be attached to a bench or a stand. Scroll saws can have a variable speed system or a two speed system. This sheet describes how to use a scroll saw. |

Controls: The controls on the scroll saw in the materials processing laboratory consist of the following:

- An on/off switch.

- A table tilt adjustment knob on the side of the machine.

- A hold down adjustment knob.

- A blade tension knob.

- A upper chuck that holds the top of the blade.

- A lower chuck that holds the bottom of the blade.

- A blower to remove dust build up.

Operation: Cutting curves and

internal cuts with the scroll saw. Refer to the following

illustrations.

- Be sure to select the right blade for the material to be cut.

- Install the bottom of the blade first making sure that the teeth of the blade are pointing downward.

- Place the top of the blade in the upper chuck.

- Adjust the tension of the blade making sure not to tight it too much or else the blade will break. (The tension is just right when the blade makes a high pinging sound when plucked.)

- Turn the blade through one complete cycle by hand with the power off to be sure that the upper blade clamp assembly does not hit the pressure foot or that the blade is not bent at the top of the stroke.

- Determine the path of the blade before cutting.

- Divide long cuts with relief cuts.

- Drill a hole larger than the blade at the point of a turn if a tight turn is needed.

- Adjust the hold down device so that it is holding the material against the table.

- Hold the work firmly against the table.

- Use a moderate pressure when feeding the material into the blade. Follow the cutting sequence.

- Cut on the waste side of the line.

- Make sure that the table is locked if cutting a bevel.

- Make an internal cut by drilling a hole in the waste side of the wood near the line.

- Slide the top of the blade through the hole and reclamp the blade in the upper chuck.

- Adjust the tension again.

- Adjust the hold down device again.

- Make the internal cut.

- Remove the work from the scroll saw by removing the

top end of the blade out of the upper chuck.

|

|

|

Potential hazards: Because of the reciprocating action of the scroll saw, the following hazards exist.

- Any body contact with the moving blade will cause injury.

- Clothing or other articles that contact the moving blade could become entangled and pull the operator's hand into the blade.

- Saw dust can be thrown out at the operator.

- The operator could slip and fall into the saw.

Safety practices: Because of those potential hazards the following safety rules must be followed.

- Be sure to perform only operations you know how to do safely.

- Always wear safety glasses.

- Never wear cloths or other articles that dangle and could catch on the saw.

- Be sure to have firm footing.

- Check the saw to make sure it is in good working order.

- Make all adjustments with the saw turned off, and unplugged in cases where the blade is or could be touched.

- Make sure the hold down is contacting the work before beginning.

- Make sure that the table is locked in the desired angle before starting.

- Check the stock for foreign objects and never saw stock containing loose or unsound knots.

- Turn off the saw to clear any materials that are near the blade.

- Avoid distractions, never look away during a cut.

- Do not allow others to crowd around the saw.

- Turn the saw off immediately if it does not sound right or if slivers of wood catch between the blade and table.

- Never let go of the stock during the cut.

- Do not saw stock that rocks on the table.

- Do not force the stock. Let the blade cut the material or else you will break the blade.

References:

Cliffe, Roger W. (1981). Woodworking: Principles and Practices. American Technical Publishers, Inc. Alsip, IL.

Spence, William; Griffiths, Duane L. (1981). Woodworking: Tools, Materials, Processes. American Technical Publishers, Inc. Alsip, IL.

ITT 252 - Materials Processing

Department of Technology

University of Southern Maine

Prepared by Amy Ouellette, 9/16/2001