Using the Vertical Milling Machine

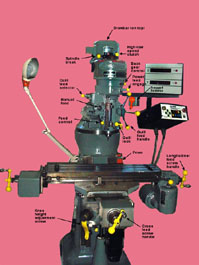

Controls: The controls on the vertical milling machine in the materials processing laboratory consist of the following:

- A magnetic power switch that must be reset if the power in the laboratory is interrupted.

- A spindle break so that the spindle nut can be loosened to take the collet out of the chuck.

- A quill feed handle to manually feed the cutter into the stock.

- A quill lock to lock the cutter in place.

- A longitudinal feed screw handle to move the stock into the cutter on an x-axis.

- A cross feed screw handle to move the stock into the cutter on a y-axis.

- A knee height adjustment screw to position the depth of the cut.

- A high and low speed clutch knob.

- A back gear control knob.

- A power feed engagement knob.

- A manual feed knob.

- A feed control knob.

- A quill feed selector knob.

- A draw bar knob.

Operation (Drilling): Milling is the operation during which the stock is moved into the cutter on an x, y or z-axis to remove stock. All the operations that are described on this sheet are using a manual feed. Refer to the following illustrations.

- Select the proper cutting bit.

- Place the bit in the spindle and make sure that the bit is at a right angle to the table.

- Tighten the spindle using the nut on the top of the milling machine.

- Place the stock in the vise and lock it in place.

- Make sure that the vise is tight and holding the material securely by hitting the handle with a rubber mallet.

- Position the cutter at the starting point.

- Place a spot of cutting oil on the spot that is to be cut.

- Select the right cutting speed, rpm, and rate of feed for the job.

- Cut the stock using the cross feed or longitudinal feed controls.

- Turn off the machine before removing the stock.

|

|

| Make sure to use a rag to remove cutters from the chuck because the cutters are sharp. | Make sure to hammer the vise handle so that the vise is nice and tight. |

Potential hazards: Because of the rapid spinning motion of the milling cutter, the following hazards exist.

- Any body contact with the moving cutter will cause severe injury.

- Clothing or other articles that contact the moving cutter could become entangled and pull the operator into the cutter.

- The work piece can come loose from the vise if it is not tightened properly and do damage to the cutter and the operator.

- Small pieces of metal chips can be thrown out at the operator.

- The operator could slip and fall into the cutter.

- The cutter and the worker piece can become very hot.

- Be sure to perform only operations you know how to do safely.

- Always wear safety glasses.

- Never wear cloths or other articles that dangle and could catch on the cutter.

- Be sure to have firm footing.

- Check the machine to make sure it is in good working order.

- Wipe up any oil that is on the floor around the machine.

- Be certain that the table is clean and dry before making a setup.

- Always make sure that work holding devices such as a vise, angle plate, dividing head, or tail stock are fastened tightly to the table.

- Select the right kind of cutter for the job.

- Make sure that the machine is turned off when putting in a cutter.

- Always make sure that the arbor, cutter, and collars are clean before mounting them in the spindle.

- Use a rag to handle sharp cutters.

- Use a rubber hammer to set the work piece in the vise securely.

- Be certain that the vise or other holding devices clear the arbor and the overarm supports.

- Select the proper cutting speed, rpm, and rate of feed for the job.

- Disengage the control handles when using automatic feeds.

- Keep hands away from the revolving cutter at all times.

- Clear chips away from the cutter with a brush.

- Release any automatic feeds after the job is complete.

- Do not allow unauthorized persons within the safety zone of the machine.

- Clean and wipe the machine when the job is finished.

- Never touch the metal chips with your fingers.

Feeds and speeds chart for the verticle milling machine

References:

Johnson, Harold V. (1973). Technical Metals. Chas A. Bennett Co., Inc. Peoria, Illinois.

Repp, Victor E. (1994). Metalwork: Technology and Practice. Glencoe Macmillan/McGraw-Hill. New York, New York. 9th edition.

ITT 252 - Materials Processing

Department of Technology

University of Southern Maine

Prepared by Amy Ouellette, 11/6/01